How Does Manual Handling Work? Exploring Its 5 Principles

How Does Manual Handling Work? Exploring Its 5 Principles

Introduction:

Manual handling is a common task in various industries that involves lifting, moving, or carrying objects by hand. While it is a necessary part of many job roles, improper manual handling techniques can lead to injuries and musculoskeletal disorders. To ensure safe and efficient manual handling practices, it is essential to follow five key principles. In this article, we will delve into how manual handling works and explore these five principles that serve as guidelines for reducing the risk of injuries and promoting workplace safety.

Risk Assessment:

Before engaging in any manual handling activity, it is crucial to assess the associated risks. A thorough risk assessment helps identify potential hazards and implement appropriate control measures to minimize or eliminate them. Factors to consider during risk assessment include the weight and size of the load, the individual's physical capabilities, the working environment, and any potential obstacles or hazards. By identifying risks beforehand, employers and workers can take necessary precautions and select appropriate equipment or techniques for safe manual handling.

Proper Technique and Posture:

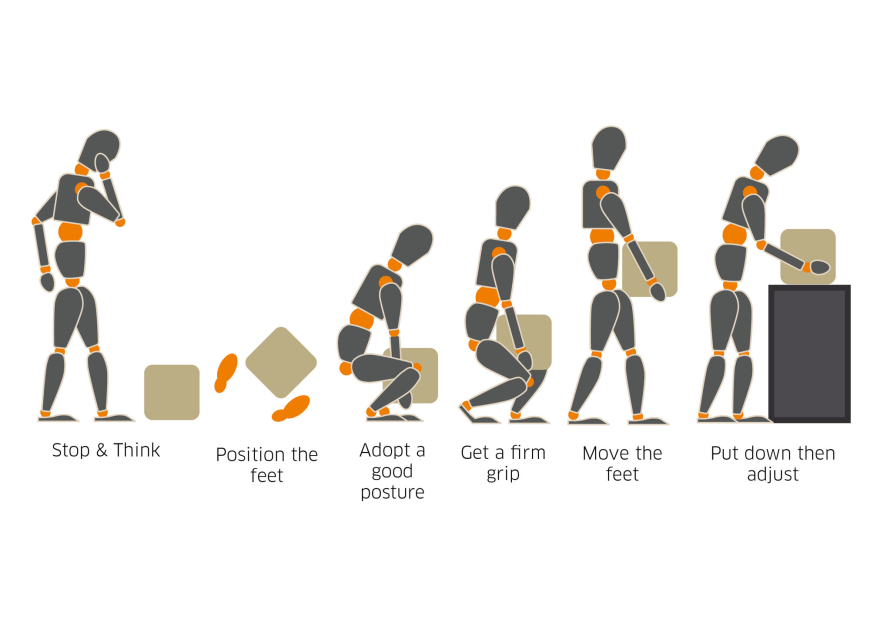

Using the correct technique and maintaining good posture during manual handling tasks are key to preventing injuries. Workers should be trained on proper lifting, carrying, and moving techniques. Some important aspects of proper technique and posture include:

- Lifting from the legs: Bend the knees, not the back, when lifting objects. This helps distribute the weight evenly and reduces strain on the back muscles.

- Maintain a stable base: Keep feet shoulder-width apart and ensure a balanced stance. This helps improve stability and prevent falls or loss of control.

- Straight back:Maintain a neutral spine position throughout the lifting process, avoiding excessive bending or twisting.

- Firm grip: Ensure a secure grip on the object being lifted, using handles or appropriate hand placement to maintain control.

- Avoid sudden movements: Lift and move objects smoothly and steadily, without jerking or twisting the body.

Use of Mechanical Aids:

When dealing with heavy or bulky loads, it is important to utilize mechanical aids whenever possible. Mechanical aids can include trolleys, hoists, forklifts, or other equipment designed to assist with lifting and moving objects. These aids reduce the physical strain on workers and minimize the risk of injuries. Employers should provide access to appropriate mechanical aids and ensure workers are trained in their safe and effective use.

Organizational and Environmental Factors:

Creating a safe work environment and implementing organizational measures are crucial for promoting safe manual handling. Employers should consider factors such as clear pathways, adequate lighting, and well-maintained floors to minimize trip hazards. They should also establish policies and procedures that promote safe manual handling practices, including training programs, regular breaks, and a supportive work culture that encourages open communication about health and safety concerns.

Training and Awareness:

Proper training and ongoing awareness programs play a significant role in ensuring safe manual handling practices. Employers should provide comprehensive training to all employees involved in manual handling tasks. Training programs should cover techniques, risk assessment, the proper use of equipment, and the importance of maintaining physical fitness and wellbeing. Regular refresher courses and toolbox talks can help reinforce safe practices and keep workers informed about any changes in procedures or regulations.

Conclusion:

Manual handling is an integral part of many job roles, but it can pose significant risks if not performed correctly. By following the five principles of manual handling—risk assessment, proper technique and posture, use of mechanical aids, consideration of organizational and environmental factors, and training and awareness—employers and workers can reduce the risk of injuries and promote a safe work environment. Remember, safety should always be the top priority, and continuous improvement in manual handling practices is essential for ensuring the well-being of workers and preventing avoidable accidents.

Online Manual Handling Course

Boost workplace safety and prevent injuries with our comprehensive Manual Handling Online Course. Master proper lifting techniques and learn essential risk assessment skills. Enrol now to protect yourself and your team!